For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

- +86-523-86183388

- +86-18036796868

- kiet@chinakiet.com

Product Features:

Replace MT / T913-2002, can be non-standard customized according to manufacturer.

Each specification can be provided with a small diameter hydraulic nut which be aimed at the small pre-tightening force of the domestic part of the host plant and the narrow installation space requirements.

Each specification can be divided into the bottom ring arrangement type and top ring arrangement type.

Supporting the use of ultra high pressure hydraulic hand pump

Supporting the use of ultra high pressure electric hydraulic pump

Supporting the use of ultra high pressure pneumatic hydraulic pump

Product Descriptions

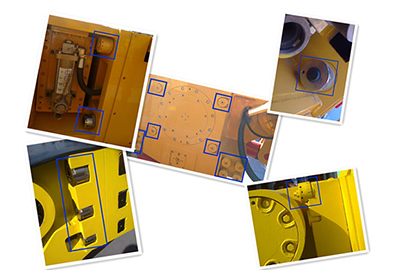

Hydraulic nut as a new type of strong fastening hydraulic tools, has been widely used in metallurgy, power, petrochemical, mining machinery, mining machine, boring machine and other heavy machinery. Coal mining machine is the realization of coal production mechanization and modernization of the major large-scale equipment, the connection parts of the use of ultra-high pressure hydraulic nut locking. As a high reliability, reliable operation of the product, hydraulic nuts in foreign new coal mine has been widely used.

Underground assembly conditions are very poor, with a manual wrench to tighten the ordinary nut, bolt preload is often not up to preload requirements, combined with complex geological structure of coal, coal mining coal often encounter faults, rocks, and repeatedly bear impact load, Vibration frequency is very large, the working environment is very bad, resulting in the main parts of the shearer connection nut loosening, resulting in shearer transmission and other parts damage, seriously affecting production. Therefore, the bolt connection between the main parts of the coal mining machine must have high reliability.

At the connecting points of major parts, use hydraulic nut between major parts and bottom brackets.can realize the electric control box of the large coal mining machine, electric machine box, electric box and the middle box of reliable connection and ensure the shearer in normal work is not loose, to ensure the safety of the use of. At the same time, the use of high strength bolts to carry out sub connections, to strengthen the effect of fixed. This effectively solves the problem of loosening due to strong vibration during normal coal cutting and faulting, reduce the failure caused by vibration of shearer, improve the reliability of shearer, greatly simplifies the daily maintenance of shearer, greatly simplifies the daily maintenance of shearer, reducing the labor intensity of workers.

| Model | Bolt size (mm) | Max. initial load (Kn) | Hydraulic area (mm2) | Outside diameter (mm) | Nut Height (mm) |

| KET-CLM-M30 | M16-M30 | 216.6 | 1571 | 74 | 66 |

| KET-CLM-M39 | M33-M39 | 349.4 | 2534 | 95 | 66 |

| KET-CLM-M52 | M42-M52 | 440.6 | 3195 | 108 | 74 |

| KET-CLM-M56 | M56 | 552.4 | 4006 | 118 | 78 |

| KET-CLM-M64 | M60-M64 | 617.3 | 4477 | 128 | 84 |

| KET-CLM-M68 | M68 | 777.1 | 5635 | 140 | 88 |

| KET-CLM-M80 | M72-M80 | 1040 | 7540 | 162 | 92 |

| KET-CLM-M90 | M80-M90 | 1462 | 10603 | 185 | 112 |

| KET-CLM-M100 | M90-M100 | 1625 | 11781 | 202 | 122 |

| KET-CLM-M105 | M100-M105 | 2079 | 15080 | 218 | 137 |

| KET-CLM-M115 | M110-M115 | 2209 | 16022 | 230 | 137 |

| KET-CLM-M130 | M120-M130 | 2339 | 16965 | 240 | 143 |

| KET-CLM-M140 | M140 | 3108 | 22541 | 276 | 153 |

| KET-CLM-M150 | M150 | 3412 | 24740 | 300 | 162 |

|

|

| File Name | Format | Language | Download File |

|---|