For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

- +86-523-86183388

- +86-18036796868

- kiet@chinakiet.com

This system is composed of 4 pump stations, 4 three-dimensional block lifters, 4 sets of frequency conversion speed control devices, 16 sets of control valve groups, 4 sets of balance valves, 8 70MPa pressure sensors, electronic control systems and 12 sets of displacement sensors, etc. .

Built in displacement sensor of oil cylinder to realize high precision horizontal positioning adjustment

The system can be equipped with optional load cells integrated in the cylinder to achieve high-precision weighing

High precision load weighing and barycenter display

Manual / automatic leveling function, safe, simple and convenient operation

High precision control (±1.0mm)

Reduce the risk of sling damage due to vibration when the crane starts and stops suddenly

Greatly improve operation speed and operator safety

Integrated development of control system

Manual / automatic free switching, convenient for field operation

Fully automatic displacement and pressure double closed-loop control

Built-in alarm function: position out of tolerance alarm, pressure over limit alarm, oil level alarm, oil temperature alarm, etc.

The system is equipped with a human-computer interface, with optional wireless remote control and local operation

Real-time storage of construction data to achieve data traceability

Automatic screen display of load center of gravity position

| Model | System Capacity (T) |

Leveling Point | Maximum Leveling Stroke (mm) |

Single Cylinder Pull Force (T) |

System Flow (L/Min) |

Max. Working Pressure (MPa) |

| KET-PHD-240 | 240 | 4 | 1500 | 60 | 2 | 31.5 |

| KET-PHD-400 | 400 | 4 | 1500 | 100 | 4 | 31.5 |

| KET-PHD-800 | 800 | 4 | 1500 | 200 | 6 | 31.5 |

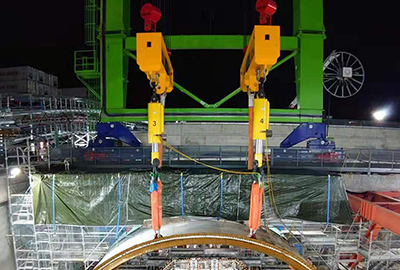

Synchronous Lifting & Attitude Adjustment of Shield Tunneling Platform

|

|

|

| File Name | Format | Language | Download File |

|---|