For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

- +86-523-86183388

- +86-18036796868

- kiet@chinakiet.com

1. Carrying capacity of each device can be customized according to actual load. Modular design can meet requirements of up to 99 devices for linkage and synchronous control.

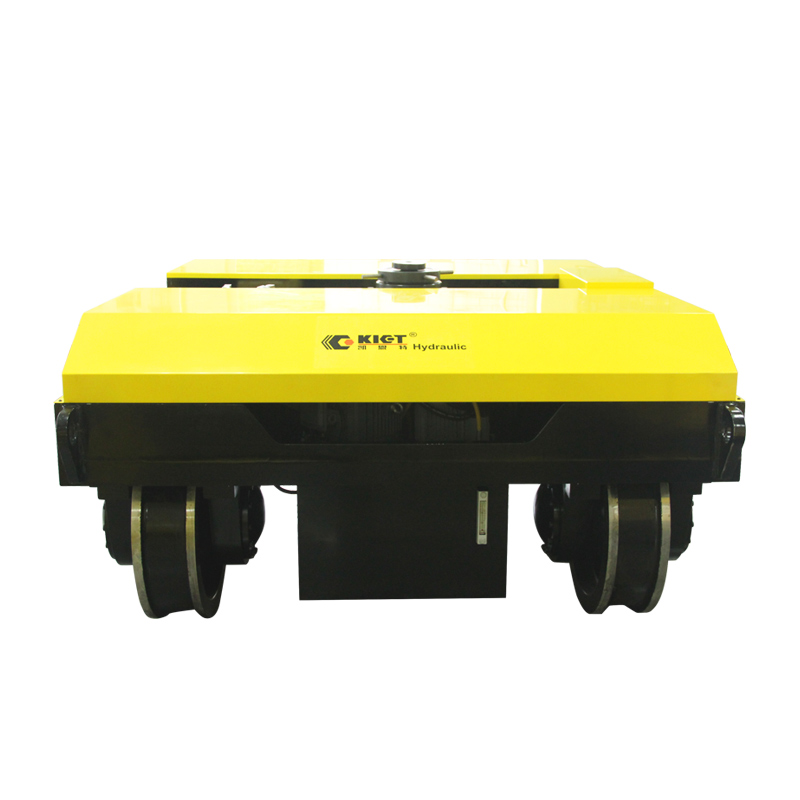

2. Hydraulic motor drive, with features of large driving capacity, small size and good waterproof performance.

3. High positioning accuracy, up to 3mm synchronous positioning accuracy. All parameters can be set in the master control room according to needs of working conditions.

4. Modern communication bus networking mode, electromechanical fluid integration design; each load bearing equipment is a complete hydraulic, mechanical and electrical control unit.

5. Supported by heavy-duty rollers, with low friction coefficient and high running stability.

6. Real-time monitoring by displacement sensors and pressure sensors to ensure on-site data construction.

7. The system is equipped with alarm functions of displacement deviation and pressure deviation to protect the safety of the site.

|

Capacity(T) |

155 |

|

Stroke/Lifting Height(mm) |

300 mm |

|

Working Pressure(MPa) |

250 |

|

Temperature |

-30℃-30℃ |

|

90°Rotation |

Manual Operation |

|

Each trolley can work independently |

Yes |

|

Working Underwater |

Yes |

|

Each trolley can work independently (including moving up and down, backwards and forwards)

|

Yes |

|

Automatic Adjustment of Overpressure Decompression |

Yes |

|

Track |

QU100 |

|

Drive |

Hydraulic |

|

Equipped with Anti-lock Braking System |

Yes |

|

Lifting Height(mm) |

300 |

|

30 |

|

Lifting Height(mm) |

120 |

|

Qty of Wheels |

4 |

|

Rotating Diameter(mm) |

700 |

|

Working Pressure(MPa) |

25 |

|

Lifting System Power |

1*7.5Kw+1*37Kw |

|

Balance Valve |

25MPa ultra high pressure balance valve |

|

Dimension(mm) |

2415×1812×1225 |

|

Stop Valve |

Emergency Protection |

|

Power |

As customer requirement |

|

Weight(T) |

6.8 |

| File Name | Format | Language | Download File |

|---|